BEEF PROCESSING

Processing

For local processing, we use Garfield Meats, or Dam Meat Company and whenever possible, have them perform an on-farm harvest. They are extremely knowledgeable butchers and offer excellent customer service. Each of them offer customizable cutting instructions, and are happy to provide you with extra assistance in getting exactly what you want from your whole or half beef.

Due to an extremely limited number of USDA inspected processing facilities in the region, we take our cattle to either Vandal Meats in Moscow, ID, or LimitBid Packing in Odessa, WA when a USDA inspected harvest or butchery is required, as is the case for all of our retail cuts.

Due to an extremely limited number of USDA inspected processing facilities in the region, we take our cattle to either Vandal Meats in Moscow, ID, or LimitBid Packing in Odessa, WA when a USDA inspected harvest or butchery is required, as is the case for all of our retail cuts.

Cutting instructions

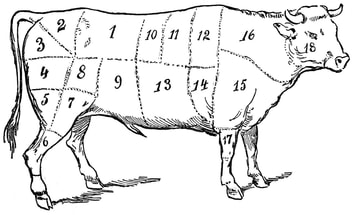

About 2 weeks before your beef is harvested, we will send you a custom cut sheet for the processor your beef is scheduled with. It's helpful to do some research on what cuts you like and what are available prior to that time, as the options can be overwhelming. Here's one resource that might be helpful to understand what's available and what to order.

Understanding what's available from your whole or half beef

Harvest

Cattle are extremely sensitive to stress, which can impact their harvest weights and affect the flavor of the meat. On our farm, our cattle lead a totally stress free life, but loading them in a trailer to head to the processor immediately creates stress. That's why, whenever possible, we prefer on-farm harvest. In that case, the butcher comes out to our farm and harvests the animal while it's happily grazing with its pasture mates. From there, the butcher transports the animal back to the plant to hang and complete the processing.

At this time, there are NO local USDA processors who perform on-farm harvests. To mitigate stress in live animals we transport to a processing facility, we deliver them a day or more before harvest is scheduled to allow them to eat, drink and recover from travel before they are harvested.

At this time, there are NO local USDA processors who perform on-farm harvests. To mitigate stress in live animals we transport to a processing facility, we deliver them a day or more before harvest is scheduled to allow them to eat, drink and recover from travel before they are harvested.

Hang weights and meat yield

There are three industry standard units of measurement you need to understand when placing your beef order: Live weight, hang weight, and cut weight.

Live weight is the weight of the animal when it's walking around. This is the unit of measurement auction houses use to sell beef on the hoof. It is not something we can easily measure on the farm (try convincing a herd of cows in a pasture to step onto a scale one at a time and wait for you to jot down their weights). Additionally, it varies hour by hour depending on hydration and rumen fill.

Hang weight or "Hot Carcass Weight" is the weight of the animal after it has been killed, skinned, gutted, with head and feet removed. This is the condition the beef hangs in the cooler after harvest, and it is the one point in the process between pasture and freezer when all carcass conditions are equal, so this is the unit of measurement used by most processors and meat sellers to base their pricing on. Hang weight in beef is about 60% of the animal's live weight. A 420 pound beef animal should hang at about 250 pounds.

Cut weight is the weight of your meat after it has been processed. It is reasonable to expect your cut weight will be about 60% of the hang weight, but this number varies considerably depending on what you requested from your processor. For example, if you order you beef entirely boned out and ground into burger, the resulting cuts will weigh considerably less than if you ordered all of your cuts bone-in. Even with minimal processing, there is a percent of the hang weight that is lost from moisture leaving the carcass while hanging. Overall, your cut weight is the sum of the weight of all your cuts. With a standard bone-in cut sheet, your 250 hang weight will translate to roughly 150 pounds of meat in your freezer.

Click the link below to read another article about hang weights and meat yield.

Live weight is the weight of the animal when it's walking around. This is the unit of measurement auction houses use to sell beef on the hoof. It is not something we can easily measure on the farm (try convincing a herd of cows in a pasture to step onto a scale one at a time and wait for you to jot down their weights). Additionally, it varies hour by hour depending on hydration and rumen fill.

Hang weight or "Hot Carcass Weight" is the weight of the animal after it has been killed, skinned, gutted, with head and feet removed. This is the condition the beef hangs in the cooler after harvest, and it is the one point in the process between pasture and freezer when all carcass conditions are equal, so this is the unit of measurement used by most processors and meat sellers to base their pricing on. Hang weight in beef is about 60% of the animal's live weight. A 420 pound beef animal should hang at about 250 pounds.

Cut weight is the weight of your meat after it has been processed. It is reasonable to expect your cut weight will be about 60% of the hang weight, but this number varies considerably depending on what you requested from your processor. For example, if you order you beef entirely boned out and ground into burger, the resulting cuts will weigh considerably less than if you ordered all of your cuts bone-in. Even with minimal processing, there is a percent of the hang weight that is lost from moisture leaving the carcass while hanging. Overall, your cut weight is the sum of the weight of all your cuts. With a standard bone-in cut sheet, your 250 hang weight will translate to roughly 150 pounds of meat in your freezer.

Click the link below to read another article about hang weights and meat yield.

Meat math-What to expect from your whole or half beef order (blog post)

Meat packaging options

There are three standard wrapping options in the meat industry. They are paper wrap, shrink wrap and vacuum seal, (aka cryovac). An overview of each is provided below:

Paper wrap

This is traditional butcher paper wrapping. Often, butcher paper is lined with plastic to prevent meat juices from saturating the paper. This wrapping option protects your meat for up to one year in the freezer.

Shrink wrap

This is a clear plastic film that is flash heated to shrink around the meat prior to freezing. Usually a double layer of shrink wrapping is applied for maximum protection of the meat. Shrink wrap is designed to prevent airflow to frozen meat which could cause freezer burn. Once meat is thawed, the wrap is no longer impermeable, and it is normal to see juices leaking out. Shrink wrap is extremely durable and resists tears and spoilage. Shrink wrap protects the meat for up to two years in the freezer, which is double the lifespan of paper wrap. It is our preferred wrapping option.

Vacuum seal

This is a clear plastic bag which is sealed after extracting all air from around the meat. Vacuum seal is very costly and is not available locally. It is delicate, punctures easily, and leaks in the seal will cause freezer burn almost immediately. If the seal is intact, vacuum seal protects meat for up to 2 years in the freezer.

Paper wrap

This is traditional butcher paper wrapping. Often, butcher paper is lined with plastic to prevent meat juices from saturating the paper. This wrapping option protects your meat for up to one year in the freezer.

Shrink wrap

This is a clear plastic film that is flash heated to shrink around the meat prior to freezing. Usually a double layer of shrink wrapping is applied for maximum protection of the meat. Shrink wrap is designed to prevent airflow to frozen meat which could cause freezer burn. Once meat is thawed, the wrap is no longer impermeable, and it is normal to see juices leaking out. Shrink wrap is extremely durable and resists tears and spoilage. Shrink wrap protects the meat for up to two years in the freezer, which is double the lifespan of paper wrap. It is our preferred wrapping option.

Vacuum seal

This is a clear plastic bag which is sealed after extracting all air from around the meat. Vacuum seal is very costly and is not available locally. It is delicate, punctures easily, and leaks in the seal will cause freezer burn almost immediately. If the seal is intact, vacuum seal protects meat for up to 2 years in the freezer.